Jun 16,2023

Technology and raw materials for sealing machines

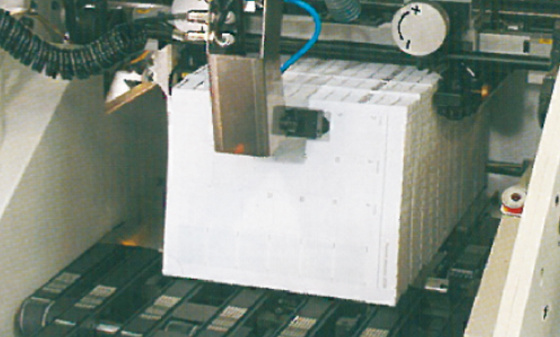

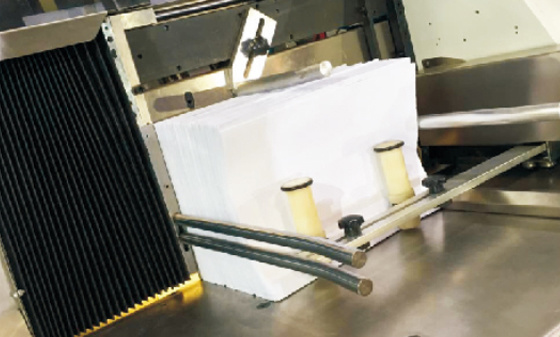

Cover machine using servo drive, hydraulic drive optical positioning and other new technologies, automatic completion of the surface paper feeding, gluing, cardboard automatic feeding, positioning, four bread edges and other processes, high precision, high speed, beautiful crimping and wrapping, is the majority of printing and packaging industry colleagues mass production: moon cakes, tea, cell phones, underwear, handicrafts, cosmetics and other packaging boxes and folders, calendars, hardcover book covers and other the most effective solution. The most effective solution.

Jun 16,2023

How does the bindery equipment work?

First, the installation of binding equipment and skills

Jun 16,2023

How do you make a booklet binding more sophisticated?

Hardcover book equipment binding work is mainly divided into three main stages: book core processing, book shell production and set of book shell.

Jun 16,2023

Slitter Introduction and Features

Slitter is a wide paper or film slitting into a number of narrow material machinery and equipment, commonly used in paper machinery and printing and packaging machinery. Previously, the speed of the magnetic powder clutch of the slitting

Jun 16,2023

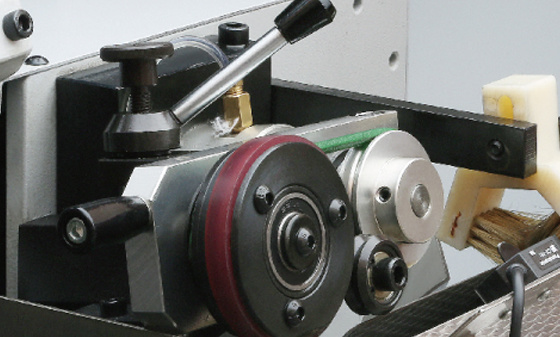

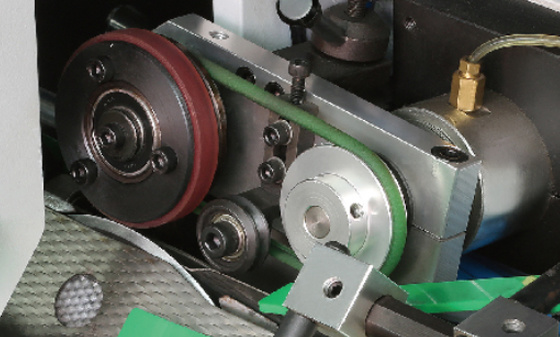

Fully automatic leather case machine solution in book case making

From the single-head machine in the 1960s to the DA series in the late 1970s, the DAS series in the 1980s, the 240/270 series after the 1990s, etc., the fully-automatic leather case machine, which has a history of 50 years, has been dominating the field of hardcover book case making with its superior compact design, stable performance, precise positioning, flexible maneuverability and high-speed production efficiency.

Jun 16,2023

Maintenance and care of the slitter

Before using the main parts of automatic slitting machine should be checked, filling lubricating oil; in the inspection and disassembly of automatic slitting machine, it is strictly prohibited to use inappropriate tools, unscientific methods of operation; every two weeks for a comprehensive cleanup and inspection of the machine; automatic slitting machine, such as a longer period of time to stop not using, it is necessary to wipe all the bright surfaces, coated with antirust oil, plus the cover plastic cover will be the whole machine cover. If the automatic slitting machine is out of service for more than 3 months, it should be covered with moisture-proof paper on the rust-proof oil; after the work is completed, clean the equipment carefully and wipe the exposed friction surfaces clean, add lubricant.

Jun 16,2023

What are the characteristics of cardboard slitting machine

Cardboard slitter is a wide paper or film slitting into multiple narrow material machinery and equipment, commonly used in papermaking machinery and printing and packaging machinery. Previously, the magnetic particle clutch speed of the slitting machine can not be high, because in operation is easy to cause high-speed friction of the magnetic powder, resulting in high temperature, shortening its life expectancy, and in serious cases will be jammed, so that the machine operation is blocked, bringing serious consequences to the production. Seriously affect the production efficiency. Glue machine's traditional control scheme is to use a large motor to drive the winding and unwinding of the shaft, in the winding and unwinding of the shaft with a magnetic powder clutch, by adjusting the current of the magnetic powder clutch to control the resistance generated by the control of the tension of the surface of the material.

Contact Us

E-mail:

sales-001@bsdmachinery.cn

Tel/WhatsApp:

+8613665882396

Address:No. 99 Jinxiu Road, Economic Development Zone, Lanxi City, Zhejiang Province